Coesia Team’s unwavering perseverance to innovation, coupled with their relentless emphasis on high-quality, cements their placement as an indispensable protagonist in the global packaging field.

Cleansing is an easy procedure, as no applications are necessary. All our piston filling machines are created with hefty-obligation chrome steel frames and all Call parts produced with food-grade materials.

Co-packers expend an important level of assets on whole-scale bottling. They need to know that your products is ready to scale to the most important concentrations.

For example, a sensor detects if a predetermined fill level is achieved then it indicators the machine to stop the filling system. With the help of those sensors, the packaging procedure runs quickly and continuously. Also, it minimizes human mistakes caused by manual packaging.

You may as well cut down blow-outs by managing the amount of solution you place inside the pouch, the amount of air is remaining, And the way luggage are protected all through transit. Logistic chain Investigation identifies The purpose(s) in which rough dealing with or drops occur during transit.

The sequence of operations starts with container preparation. This requires organizing and placing the containers on the conveyor for transport through a cleaning station. The cleaned containers then enter a filler.

An incredible thought is the main and most crucial stage towards launching your individual consume corporation, but…

The carbon dioxide and nitrogen combination is more risky to bacteria, yeasts, and also other microorganisms that cause food spoilage and decay, indicating they might’t wreak their typical havoc on the fresh new food.

In an endeavor to bolster employee basic safety and conform to voluntary specifications for example those delineated because of the American Nationwide Requirements Institute (ANSI), manufacturers are integrating advanced security apparatuses within their packaging machinery. These breakthroughs are strategically made to diminish the chance of injury and comply with compliance requirements.

) A lot of models of the measurement/cost use vacuum packaging machine glass for the cover. With no data in The outline, I'd assumed it had been a glass top but appears to get a thick plastic. My past unit unsuccessful a result of the plastic deal with cracking. The manual also leaves one thing to be ideal With regards to oil administration. The Directions for Original oil filling is absolutely nothing but worthless word salad. Doesn't say the amount of oil is Study Far more

Most manufacturers of packaging solutions supply session providers for the creation of your respective best powder packaging machine to higher accommodate your exact desires.

Furthermore, it doesn’t oxidize with enzymes and lipids precisely the same way that oxygen does. This gasoline mixture effortlessly replaces the oxygen that’s removed in the vacuum chamber without the need of contributing anything at all distinctive or unappealing to the scent, flavor, or visual appearance in the food.

The products characteristics, just about anything from drinking water to peanut butter, establish the know-how very best suited for our customers. Accutek’s timed stream vacuum packaging machine volumetric filling machines are very best suited for filling liquids with minimal to medium viscosity.

We’re below to answer all of your concerns and we have the proper issues for yourself, also! This makes sure you don’t squander time and money on orders that don’t satisfy your requirements.

Tia Carrere Then & Now!

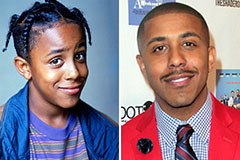

Tia Carrere Then & Now! Marques Houston Then & Now!

Marques Houston Then & Now! Bill Cosby Then & Now!

Bill Cosby Then & Now! Jaclyn Smith Then & Now!

Jaclyn Smith Then & Now! The Olsen Twins Then & Now!

The Olsen Twins Then & Now!